Galvanized Partition Light Gauge Steel Stud and Track Roll Forming Machine 7.5 kw

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

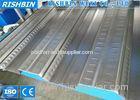

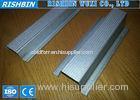

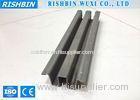

Galvanized Partition Light Gauge Steel

Galvanized Partition Light Gauge Steel Stud and Track Roll Forming Machine 7.5 kw

Description of light gauge steel stud and track roll forming machine

This kind of machine is PLC control, automatic forming & cutting. The drywall track profile can be as per required.

Structure of light gauge steel stud and track roll forming machine

This roll forming machine consists of 3 tons manually uncoiler, chain driven transmission, forming rollers, mainframe(including guiding platform), cutting, hydraulic system and stacker.

The whole production process including punching and cutting is controlled by PLC, rollers manually adjustment if different dimensions of manufacturing is needed.

Specification of light gauge steel stud and track roll forming machine

| Name | Item | Description |

| Galvanized Partition Light Gauge Steel Stud and Track Roll Forming Machine | Production Material Thickness | 0.5mm-1.0mm |

| Number of Stations | 13 stations | |

| Forming Speed | 815M/min(Including the time of punching and cutting stop) | |

| Roller Material | GCr15 with heat treatment and hard chrome-plated HRC58-62 | |

| Spindle diameter | 70mm | |

| Spindle material | High-quality steel 45 quenched and tempered after finishing treatment | |

| Power of Main Motor | 7.5 KW | |

| Power of Hydraulic Station | 4.0 KW | |

| Cutting | flying saw used after forming | |

| Electronic Controlling System | Full-frequency PLC controlling system | |

| Material of cutting blade | Cr12 quenched |

Working process of light gauge steel stud and track roll forming machine

Coiler loading → feeding-in with guiding (metal sheet is guided into the first forming station) →rolling & forming→ flying saw cutting → stacker running out

Composition of light gauge steel stud and track channel roll forming machine

Manual de-coiler…………………………..............…1 unit

Roll forming main machine………………………. …1 unit

Control panel…………………………………………...1 unit

Hydraulic station…………………………………… …1 unit

Manual out table……………………… ……………….2 unit

Spare tools……………………………………………...one box

Sample Drawing

Our advantage

- High Quality

- Reliable

- Durable

- Reasonable Price

- Good after Service

- 1 Year Warranty

- More Than 10 Years Experience

Company introduction

Rishbin was founded in 1999. With more than ten years' development, now it becomes a leading professional supplier in the field of roll forming machinery industry, and exports its quality production

line to the markets all over the world.

We are one of the leading suppliers and manufacturer in china and have been supplying and making roll forming equipment for the metal building construction industry for a long time.

Contact us

For more information, please contact us freely.

Skype: sarahrishbin

Mobile: +86-18118899986

E-mail: sarahrishbin@gmail.com

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

RISHBIN WUXI CO., LTD [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)