Professional Servo Feeding Upright Frame Cold Forming Machines with 18 Stations

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Professional Servo Feeding Upright Frame Cold Roll

Professional Servo Feeding Upright Frame Cold Roll Forming Line with 18 Stations

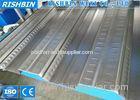

Structure of Upright Frame Cold Roll Forming Line

This roll forming machine consists of 3 tons hydraulic decoiler, servo feeding system, high speed punching machine, chain driven transmission, forming roller, mainframe(including guiding platform), cutting device, hydraulic system, electric controlling system and stacker.

Main Specifications of Upright Frame Cold Roll Forming Line

| Product Name | Item | Description |

| Upright Frame Cold Roll Forming Line | Forming speed | 10-15 m/min |

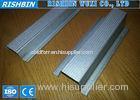

| Number of stations | 18 stations | |

| Roller material | High quality 45 forged chrome-plated hardware | |

| Shaft diameter | 80mm | |

| Shaft material | Using high-quality steel 45 quenched and tempered after finishing treatment | |

| Power of main motor | 11.0kw | |

| Power of hydraulic station | 5.5kw | |

| Hydraulic station pressure | 1012 Mpa | |

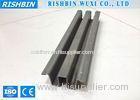

| Cutter material | Cr12 quenched | |

| High speed punching machine | 80 tons | |

| Electronic controlling system | full-frequency PLC controlling system, error of cutting length ≤ 2mm |

Main Components

|

Decoiler / Uncoiler |

1 Unit |

|

Feeding Guide |

1 Unit |

|

Main Roll Forming Machine |

1 Unit |

|

Hydraulic Cutting Device |

1 Unit |

|

Hydraulic Station |

1 Unit |

|

PLC Computer Control Board |

1 Unit |

|

Runout Table |

2 Units |

Working Flow of Upright Frame Machine

Coil loading → servo feed-in (sheet metal is put by guiding platform) → straightening→ high speed holes punching → forming → hydraulic cutting → stacker

Main Character of Upright Frame Cold Roll Forming Line

1. Simple structure,good appearance since the whole machine is used profiled steel structure and wholly manufacturing after welding, in order to make it running stable and reliable.

2. Completely automatic cutting, accurate length and position, trim cutting for rear of profile sheets, no deformation.

3. Easy installation, good performance for manufacturing in factory.

4. Low noise, high efficiency.

Our Advantage

- High Quality

- Reliable

- Durable

- Reasonable Price

- Good after Service

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

RISHBIN WUXI CO., LTD [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)

You May Like:

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español