Construction Structure C Z Section Roll Forming Machine Quick Interchanged

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Quick Interchanged C Z Section Roll Forming Machin

Quick Interchanged C Z Section Roll Forming Machine for Construction Structure

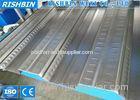

Specifications of C Z section roll forming machine

- Purlin width :80-350mm,height: 40-80mm,small rib: 14-25mm

- Coil thickness:1.2-3.5mm Q195~235, zinc coils & Hot Rolled coils

- Working speed: 10-25m/min (not containing punching and cutting time )

- Forming roller: 17steps

- Leveling roller:5steps (up 2 and down 3)

- Rectifying: one step

- Feeding & guiding: 2 sets ,4 rollers

- Material of roller: GCr15, quenched

- Material of main shaft:45 steel

- Main motor: 15KW

- Feeding, leveling motor power: 7.5 KW

- Hydraulic pressure: 15-20MPa

- Hydraulic power: 7.5 KW

- Two servo motor and four encoder

- Transmission: Transmission by Chains 1.2Inch double line

- Main dimension: 11000mm x 1400mm x 1400mm (L x W x H)

- Total weight: 14000kg

Main Components

Decoiler / Uncoiler | 1 Unit |

Feeding Guide | 1 Unit |

Main Roll Forming Machine | 1 Unit |

Hydraulic Cutting Device | 1 Unit |

1 Unit | |

PLC Computer Control Board | 1 Unit |

Runout Table | 2 Units |

Standard of hydrauic decoiler and manual decoiler

Hydraulic decoiler

- single head to put the coil hydraulic fiow over device

- coil spec:508*1300mm

- flow over range: 460-520mm

- oil cylinder:160*90mm

- drive by hydraulic brake

- capacity:5T,10T,20T

- Power of decoiler:4KW cycloid motor

Manual decoiler

- Dimensions: 1700mm*1000mm*800mm

- Width of feeding: 600mm

- Capability: 5 Ton

- Bound of expand &fight: 450mm—510mm

- Mode of expand &fight: inner expand &fight by manual

- Way of feeding: manual

Details of punching and cutting

- Punching mold: Cr12 HRC 58-62

- Machine with 3 sets punching system

- Punching with hydraulic drive

- Punching in longitude wise controlled by PLC, punching at horizontal wise adjusted by manual hand wheel.

- Punch details as shown in drawing.

- Hydraulic Cutting before forming: Cut the sheet before roll forming to required length.

- Cutting motion: The main machine not stop and the continue punching and cutting.

- Material of blade: CR12with heat treatment

- Length measuring: Automatic length measuring

- Tolerance of length: 3m+/- 1.5mm

Production characteristic

1: This kind of machine can produce C , Z two profiles, through the exchange side of the roller up and down position to achieve C , Z purlin conversion , just need about half an hour to achieve saving time. This machine also can automatically adjust roller horizontal distance to achieve C or Z purlins pf the width with high precision , but also save time to increase production.

4: This line main forming drive adopt reducer motor and frequency conversion control, speed control…

5: It is quick and easy to operate the machine, and beautiful appearance, high production efficiency, forming speed up to 20m/min.

Contact us

For more information, please contact us freely.

Skype: sarahrishbin

Mobile: +86-18118899986

E-mail: sarahrishbin@gmail.com

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

Company Info

RISHBIN WUXI CO., LTD [China (Mainland)]

Business Type:Manufacturer

City: Wuxi

Province/State: Jiangsu

Country/Region: China (Mainland)